Commercial kitchens face all sorts of challenges when it comes to managing food waste. Finding the best way to deal with huge quantities of prep waste, leftovers and other scraps is no easy task, especially when it comes to transporting waste from one area of the building to another. That's why our WasteStar FC vacuum system is such a great solution. With its modular design, high-quality processing and top-notch ergonomics, it's the most reliable way to get the job done.

Freestanding infeed station

Infeed station attached to fully automatic machine

Infeed station integrated above dishwasher feeding section

Infeed station attached to rack sorting station

Infeed station at front of dishwasher feeding section

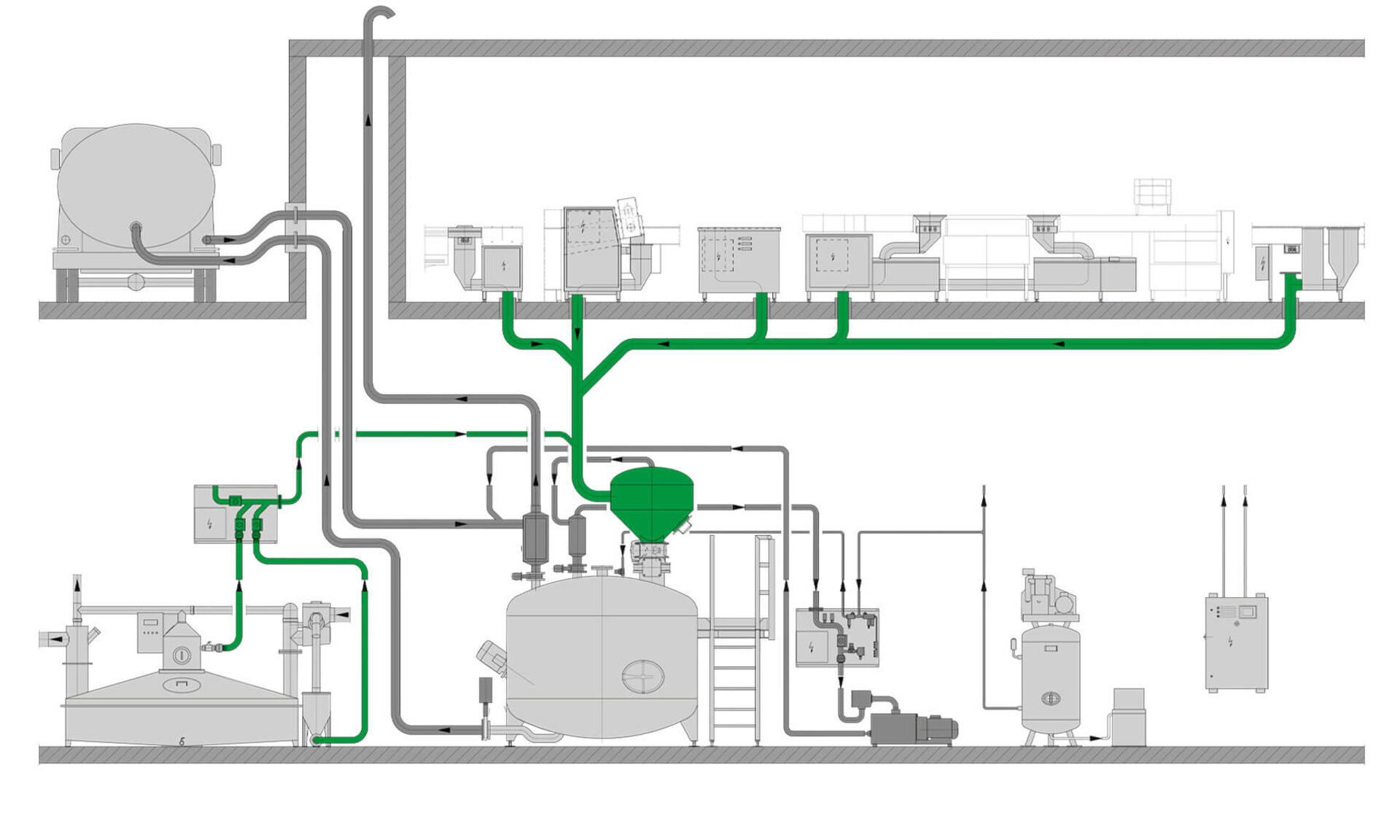

A vacuum is generated in the suction tank. The food waste is shredded on its way to the storage tank.

The shredded, homogenised waste is stored in the tank without requiring any additional refrigeration.

External control panels allow the storage tank to be emptied into a tanker automatically via the extraction pipe.

The biomass in the storage tank is periodically pumped into tankers and sent to a biogas plant to generate sustainable energy.

The MEIKO GREEN 'GreaseSeparator connect' system removes fats, oils and grease from wastewater. The grease trap is connected directly to the food waste treatment system.

The vacuum pump generates the vacuum required to suck the waste through the piping system.

We can develop a bespoke system that takes into account your individual workflows. To boost efficiency, infeed stations need to be located where the organic waste is generated. The disposal points can be integrated in food preparation areas, next to sorting belts, or directly within your warewashing system. A vacuum system is then used to suck the waste through the stainless steel pipes and into the storage tank. Everything can be tailored to your needs – from the exact type of infeed station to the strength of the vacuum and the sequence and timing of the suction process. So, instead of dirty buckets, process water, expensive cold storage and unpleasant odours, you benefit from outstanding hygiene, superior technology and maximum flexibility! And we can even incorporate a grease trap to make your system complete.